Researcher Interviews Vol.32024.2.5

A journey of exploring the further potential of strong and light aluminum—material development is an unlimited source of dreams!

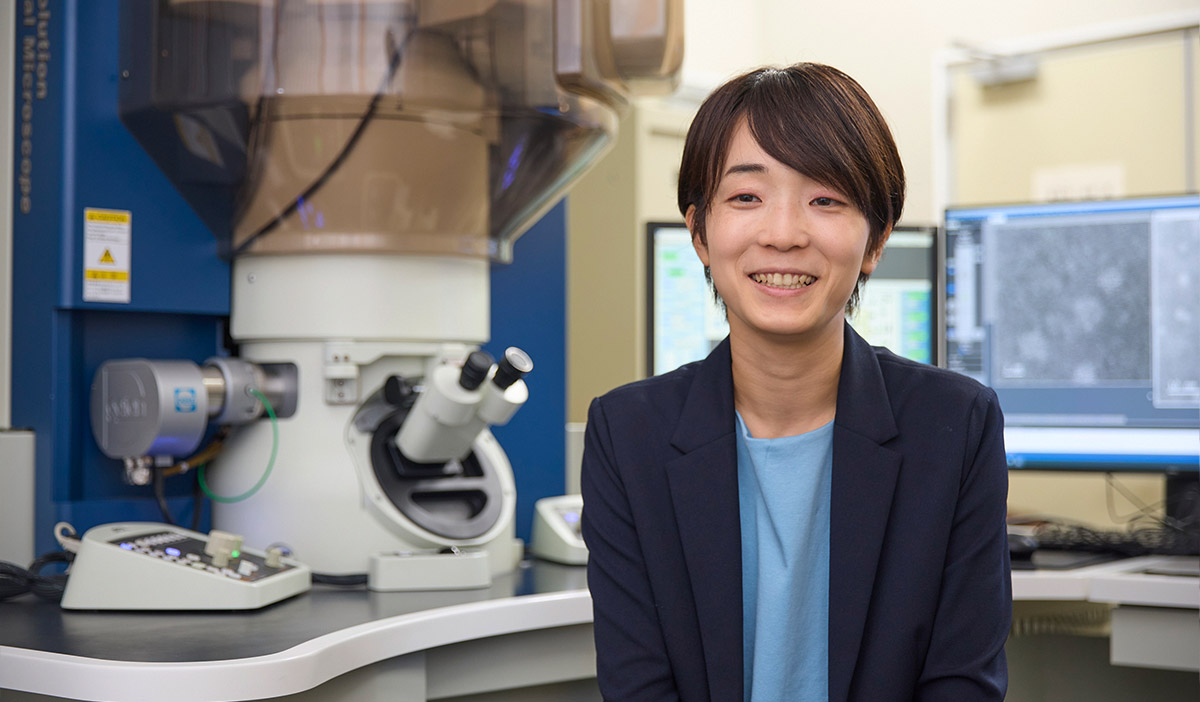

Mami MIHARA-NARITA

Assistant Professor

Department of Engineering (Physical Science and Engineering) , Graduate School of Engineering

Strong and flexible,

both in research and in planning own life

- Fields of Research:

- Materials Function and Design / Nanotechnology/Materials / Metallic materials

- Research Keywords:

- Dissimilar metal joining, Microstructure control, Magnesium alloys, Aluminium alloys

QWhat kind of research are you doing?

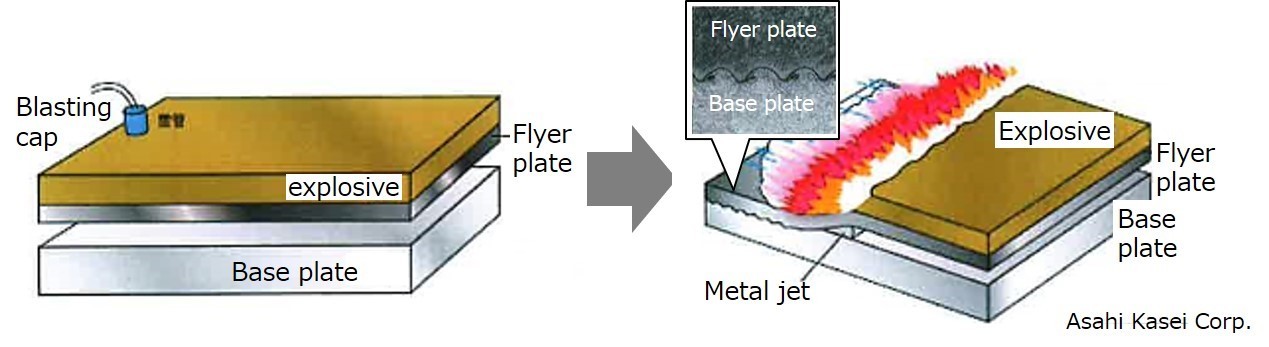

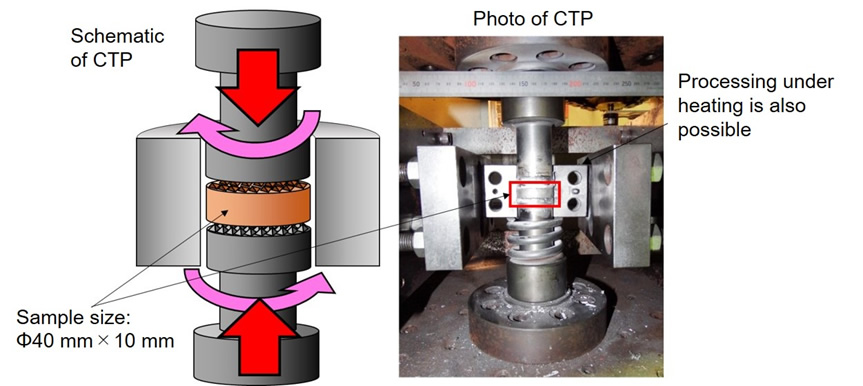

In recent years, the development of “multi-materialization,” which means using the right material in the right place, has advanced, and “lightweight material” and “bonding technology” have become the keys to the development of automobile and aircraft materials. Aluminum is a type of light metal and is relatively new compared to iron and copper, which have long been used as materials. Although the light metal is essential for achieving weight reduction, there are still many things that remain unknown about its properties. In my research, I use various techniques to control the microstructure of aluminum with the aim of improving its properties and elucidating the strengthening mechanism. The techniques include various heat treatments, compressive torsion processing, bonding with dissimilar metal using explosives, and 3D printing using powder of wire aluminum samples.

The above illustration describes a setup overview of the explosive welding method used to join the dissimilar materials of magnesium alloy and aluminum alloy. In conventional bonding methods, the formation of an interlayer consisting of brittle intermetallic compounds at the interface results in reduced strength in the joint. Our study found that the use of the explosive welding suppressed the formation of the interlayer and provided higher bonding strength.

The above show a setup overview of Compressive Torsion Processing (CTP). This method can introduce a huge strain inside the material by compressing and twisting the material simultaneously, which makes it possible to refine the microstructure

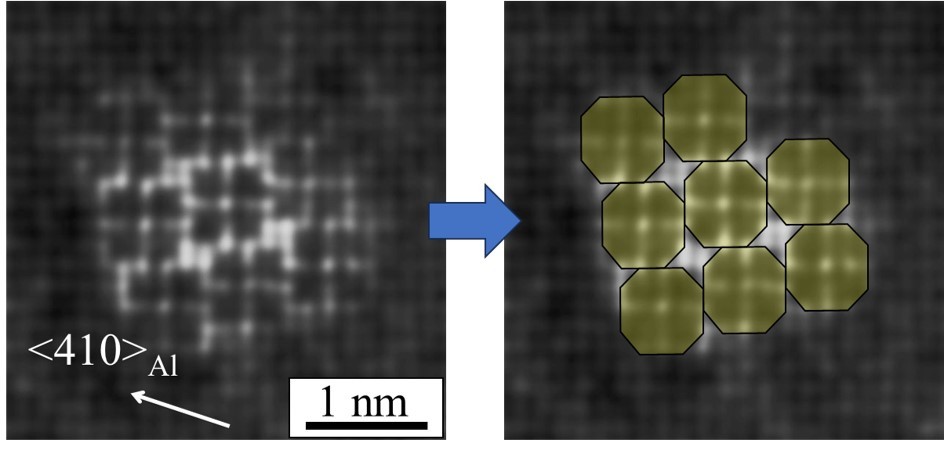

These are High-Angle Annular Dark Field Scanning Transmission Electron Microscopy (HAADF-STEM) images of nanostructure in a 7000 series aluminum alloy . As shown in the figure on the right, atoms (Al, Mg, and Zn) are arranged in a unit structure, and this nanostructure contributes to the high strength.

Macroscopic properties, such as strength and ductility, can be improved by controlling the micro- and nanostructures of a material.

QWhat inspired you to pursue a career in research?

I first encountered aluminum when I was enrolled in a master's course. I was intrigued by the process of how the hardness of aluminum changes with heat treatment and how it hardens even at room temperature over time. I was captivated by this material. Since then, I have become immersed in the world of aluminum research, studying with various methods, such as transmission electron microscopy, positron annihilation, and three-dimensional atom probe, so as to explore how the aggregation of atoms (clusters) are formed by heat treatment. I had the opportunity to meet a female researcher who was active in the same academic society. I was drawn to her dedication to research, including studying abroad, which led to my decision to enter a doctoral program. When I studied at the Norwegian University of Science & Technology (NTNU) as a doctoral student, researchers there took great interest in my research. I still maintain a cooperative relationship with the university. Since my encounter with aluminum, I have met many people both in Japan and overseas. I am really glad that I came across aluminum because meeting these people has given me encouragement and support in my career as a researcher. After graduation, I joined an aluminum manufacturer, and was very impressed by the fact that the company’s daily efforts to solve many problems and challenges delivered to the world materials of good quality. After that, I took up my current post, but one thing that has remained unchanged is my desire to elucidate the strengthening mechanism of aluminum. I will continue on this path, following my passion and love for research.

QYou have established the Research Subcommittee, Age-Hardening Behavior of 7000 Series Aluminum Alloys and serve as Chairperson. Please share with us the activities of the subcommittee. Also, in association with the launch of this group, please tell us if there was anything that impressed you.

Al-Zn-Mg alloys, which have the highest strength among aluminum alloys, are used in structural members for aircraft, railway vehicles, automobiles, etc. Aluminum alloys are usually hardened (age hardened) by forming fine precipitates through heat treatment, which requires rapid cooling (water cooling) during the solution treatment performed at that time. However, it is known that 7xxx series alloys can achieve high strength under certain conditions even when they are slowly cooled (furnace cooling), and there is an urgent need to understand the hardening mechanism of the 7xxx series alloys after furnace cooling and develop processes to achieve even higher strength and other properties such as stress corrosion cracking (SCC) resistance, since the use of furnace cooling has the advantage of reducing industrial processes Because of this, I launched a research subcommittee of Age-hardening behavior of 7000 series aluminum alloys at The Japan Institute of Light Metals. With approximately 20 researchers gathered from industry and academia, we engage in research activities using a variety of methods. The participants have a strong interest in this research theme, and I feel that the group activities are also useful because they provide opportunities to exchange information about research methods and the latest research trends. Researchers tend to be lonely at times, so I keenly feel that connecting with other researchers is very important. The Institute is putting systems in place to help young researchers come up with research themes with out-of-the-box thinking and give a concrete form to the themes.

QWhat do you find interesting about your research, what difficulties have you faced, and what is your focus as a researcher?

Aluminum may be a familiar material to everyone. Actually, it has a wide variety of types, such as different types of additive elements, heat treatment, the manufacturing process, and so on. Aluminum is produced by the method suitable for each purpose. This applies not only to aluminum, but to other metal materials in general. The development of "materials," which are the basis of all things, is still full of possibilities with many unknown phenomena. You sometimes obtain results that are different from your expectations or are not as described in a textbook, but in times like this, you have a chance for new discovery. Would that make you excited? I want to be strong and flexible, both in my research and in planning my own life. When something unexpected happens, or a valuable encounter or opportunity presents itself unexpectedly, I try to flexibly respond based on the situation I am in. Also, it is quite important to have people around you with whom you can consult about your daily life

QTell me about your future goals (both research and life-related).

I wrote in another interview, “One of my dreams is to participate in international conferences, taking my son with me,” which soon came true. I made two overseas business trips (Wien and Columbus) with my son in 2023. These trips became a great experience for us. Another dream is to conduct research abroad living with my son, which also makes me concerned because of various obstacles we may encounter if it is a long-term stay. In addition, my future goal is to uncover new materials and manufacturing methods that will contribute to the SDGs, by studying aluminum throughout my life. I would also like to be involved in activities that convey the fun of studying materials and metals to the next generation.

Assistant Professor Narita reuniting at an international conference (Thermec2023, Wien) with Professor Lee from the University of Toyama (center), who has been helping her since her student days, and Professor Holmestad from NTNU (right), who was in charge of accepting international students.

Career summary

Education

March 2017 Ph.D. in engineering, Department of Metallurgy and Ceramics Science, Graduate School of Engineering, Tokyo Institute of Technology

Professional Carrier

April 2020-present Assistant Professor, Graduate School of Engineering, Nagoya Institute of Technology, Japan

April 2017-March 2020 Researcher, The UACJ Research & Development Division, Japan

Professional Memberships

・The Japan Institute of Light Metals (JILM)

・Research Subcommittee “Age-hardening behavior of 7000 series aluminum alloys”

・Gender Equality Committee

・The Japan Institute of Metals and Materials (JIMM)

・Japan Welding Society (JWS)

・Research Committee for Joining & Materials Processing for Light Structures

・Young Members Committee

・Japan Foundry Engineering Society (JFS)

Awards

2023

12th New Chemical Technology Research Encouragement Award, Japan Association for Chemical Innovation (JACI)

Lecture Encouragement Award, the Research Committee for Joining & Materials Processing for Light Structures, Japan Welding Society

Excellence Award, Center for Innovative Young Researchers, Nagoya Institute of Technology

2022

Special Award for Young Researchers, The Society of Japanese Women Scientists

Award for Excellence, the President’s Award, Nagoya Institute of Technology

Excellence Award, NITech Future of Engineering Opened by Woman Award, Nagoya Institute of Technology

40th Light Metal Encouragement Prize, The Japan Institute of Light Metals

Encouragement Award, Center for Innovative Young Researchers, Nagoya Institute of Technology

2021

Most Promising Graduate Award, the First Promising Graduate Award Grand Championship, The Japan Institute of Light Metals

2019

11th Light Metal Outstanding Female Award, The Japan Institute of Light Metals

2014

Light Metal Promising Graduate Award (FY2013), The Japan Institute of Light Metals

Hobbies and interests

Currently, I can hardly find time for immersing myself in my main hobby (playing the French horn), but I can still enjoy musical instruments (such as the piano, violin, and Japanese drums) and conversation in English through the lessons my son is taking.