Initiative - CO₂ emissions reduction! Ceramics made at low temperature and without firing to underpin the age of carbon neutrality

Category:News|Publishing : November 8, 2022

It is generally believed that ceramics entail a high-temperature firing process. Firing, of course, consumes energy and generates CO₂ emissions. Approximately 60% of the CO₂ emissions in the manufacturing of ceramics comes from the firing process. This production method goes against the target of achieving a carbon neutral society by 2050. At the Advanced Ceramics Research Center of the Nagoya Institute of Technology, whose motto is to overcome conventional wisdom by leveraging knowledge, we are conducting research on how to make ceramics at low temperature, and ultimately how to obtain ceramics without firing.

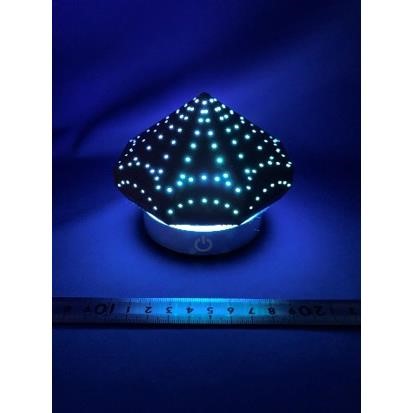

There are many things that can be achieved by removing the firing process. CO₂ emissions reduction, energy saving, and lower costs are just some of the advantages of ceramics production without firing. For example, it will become possible to combine different materials (plastic, wood, metals, etc.) that previously were unable to be combined. The photo shows a light object created by embedding resin optical fiber in non-firing ceramics. This is just for display, but we can foresee that the combination of different materials can realize new functions. For example, the incorporation of electronic circuits is one of many possible options. In the future, in combination with a 3D printer, it might become possible to construct buildings in space.

Through these research activities, we engage not only in the production of physical items, but also in the development of human resources. Students are asked to propose ideas for materials useful for environmental protection using this technology, and good proposals proceed to the stage of full-scale research. Our educational framework has been designed to encourage individual students to identify problems and conduct research autonomously so that they will become researchers or engineers who can create new value and serve as trailblazers in the future. Located in Tajimi City, the largest ceramics production center in Japan, we have been promoting industry-academia partnerships to share local companies' technology and our faculty members' expertise. This provides opportunities for students to experience internships at our center and for corporate engineers to receive recurrent education.

Our research findings, related events, annual reports, and other information are available on our website, so feel free to take a look.

▷ Advanced Ceramics Research Center(Link to Japanese website)

Team "P01TERGEIST" reports to the President upon winning the METI Minister's Award at the 17th Crisis Management Contest Shirai Laboratory's research paper selected as "Front Cover" of Journal of Materials Chemistry C

Japanese

Japanese