RESEARCH NEWS - Towards Efficient Room-Temperature Fluorine Recovery from Fluoropolymers

Category:News|Publishing : September 26, 2025

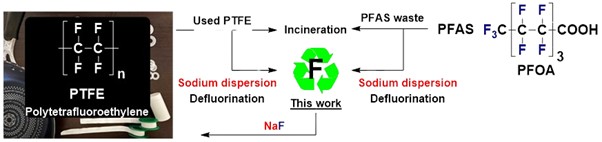

Polytetrafluoroethylene (PTFE) is a synthetic fluorine-based polymer with a wide range of applications, including non-stick cookware production and electrical and optical fiber cable coating, owing to its high durability, thermal stability, and low friction. Ironically, its durability also presents an environmental challenge for its disposal. PTFE is mainly disposed of via incineration, landfilling, and defluorination. However, incineration requires high energy and involves the release of hydrogen fluoride, which is highly corrosive. Meanwhile, landfilling leads to an environmental burden of undegraded PTFE. By contrast, defluorination, in which PTFE is converted into its constituent fluorine compounds, is eco-friendly as it enables polymer recycling. Unfortunately, traditional PTFE defluorination either requires high-temperature reactions (>500 °C) or complex reagents for the more manageable low-temperature reactions (<100 °C). Moreover, in either case, the efficiency of fluorine recovery has not been explored.

To address this gap and improve fluorine recovery via PTFE defluorination, a group of international researchers led by Professor SHIBATA Norio from Nagoya Institute of Technology (NITech) in Japan recently developed a novel defluorination method that utilizes sodium dispersion to degrade PTFE and recover fluoride ion under mild conditions. Their study, which involved the contributions of Mr. ARAKi Taichi and Mr. OTA Hibiki from NITech, was published in the Nature Communications journal on July 15, 2025.

In the new method, a remarkable fluoride ion yield (in the form of sodium fluoride) of up to 98% was achieved from PTFE using sodium dispersion (2 equivalents) in tetrahydrofuran (THF) at a reaction temperature of 25 °C and a reaction duration of 12 hours. The major advantage of this defluorination approach is that it can operate at room temperature, avoiding the need for extreme conditions. To further verify fluoride recovery, the team examined the elements in the black residue obtained after PTFE degradation under optimized conditions using spectral analysis and estimated that the proportion of fluoride lost from PTFE was 93.5%.

Further analysis of this residue using X-ray diffraction, Raman and infrared spectroscopy, and nuclear magnetic resonance confirmed efficient fluoride recovery from PTFE. In addition, morphological analysis using scanning electron microscopy with energy-dispersive X-ray spectroscopy revealed that the defluorination process transformed PTFE's morphology, from an initial dense, irregularly shaped grainy texture with smooth surfaces into a black residue with a highly irregular rough surface showing cracks.

Furthermore, the team examined the applicability of this method for other fluorine-based compounds and found that it could efficiently recover fluorine (up to 97%) from per- and polyfluoroalkyl substances (PFAS) as well, namely perfluorononanoic acid, perfluorooctanoic acid, perfluorobutanesulfonic acid, and trifluoroacetic acid, once the reaction duration and sodium dispersion quantity were properly fine-tuned. Prof. SHIBATA notes, "In addition to PTFE, other fluorine-containing compounds are major environmental pollutants. Our defluorination method could effectively degrade PFAS, indicating its broad applicability."

As already noted, PTFE and PFAS, despite their utility, pose a major environmental concern in relation to their effective degradation. Developing an effective and robust defluorination method could not only help mitigate such environmental hazards but also enhance the recovery and circulation of fluorine as a valuable resource. "In contrast to the conventional PFAS defluorination methods that require plasma processing or incineration at elevated temperatures, our defluorination method is an eco-friendly, non-energy-intensive approach with reduced toxic gas emissions that not only improves fluorine resource utilization but can help minimize our dependence on fluorite in the future," concludes Prof. SHIBATA.

Reference

|

Title of original paper |

Room-temperature defluorination of PTFE and PFAS via sodium dispersion |

|

Journal |

Nature Communications |

|

DOI |

10.1038/s41467-025-61819-6 |

|

Latest Article Publication Date |

July 15, 2025 |

About Professor SHIBATA Norio

SHIBATA Norio is a Professor of Chemistry at the Department of Engineering, and Department of Nanopharmaceutical Sciences at Nagoya Institute of Technology in Japan. He received his PhD from Osaka University in 1993. Prof. Shibata is a recipient of many awards, including the Takeda Pharmaceutical Company Award in Synthetic Organic Chemistry, Japan (2000), Fujifilm Award in Synthetic Organic Chemistry, Japan (2003), Incentive Award in Synthetic Organic Chemistry, Japan (2004), RSC Fluorine Prize (inaugural prize in 2005), 20th Lecture Award for Young Chemists in Chemical Society of Japan (2005), Fluorine Chemistry Research Incentive Award in Research Foundation ITSUU Laboratory (inaugural prize in 2009), The Pharmaceutical Society of Japan Award for Divisional Scientific Promotions (2010), Prizes for Science and Technology, The Commendation for Science and Technology by the Minister of Education, Culture, Sports, Science and Technology (2014), CSJ Award for Creative Work in Chemical Society of Japan (2015), Chinese Chemical Society, W.-Y. Huang Fluorine Prize (2015), Lecture Award in the International Congress on Pure & Applied Chemistry (ICPAC) 2018 (2018), ACS Award for Creative Work in Fluorine Chemistry (2019), The 18th (2018) Green and Sustainable Chemistry Awards by the Minister of Education, Culture, Sports, Science and Technology (2019), The Society of Iodine Science Award (2019), Fellow of Royal Society of Chemistry (2021, RSC, UK) and Chair of Excellence (LabEx SynOrg, France, 2022-2023). He is also registered as an excellent reviewer in Publons (2021). His research interests cover a wide range of synthetic and medicinal fluorine chemistry.

Funding information

The study was supported by the CREST program of the Japan Science and Technology Agency, entitled Precise Material Science for Degradation and Stability (grant number: JPMJCR21L1), CMC Research Institute, Japan, and the FIU program of the Universitat de València.

Contact

Professor SHIBATA Norio

E-mail : nozshiba [at] nitech.ac.jp

Website : https://pure.nitech.ac.jp/en/persons/norio-shibata

*Please replace [at] with @ when contacting.

[Initiative Introduction] Research and development of mixing technology that is essential for all industries and daily life NITech Staff Member Participates in Erasmus+ Programme at FAU, Germany

Japanese

Japanese